Keyseating machine

After accumulating years of experience in repairing and reconditioning keyseating machines from every manufacturer, we have developed our own keyseating machines. This includes taking account of requests from experienced users. The focus is always on particularly simple and, therefore, fast operation when constructing and improving our keyseating machines. Request our reference list and hear this confirmed by actual users.

- Particulary quick and easy to set up

- Easy to operate even for inexperienced staff

- Setup errors minimised

- Low maintenance requirement

- Adjustable return speed which avoids built-up edges on keyseating cutters when machining

high-alloy materials - The keyway cutter can be lifted right out of the keyway for the return stroke

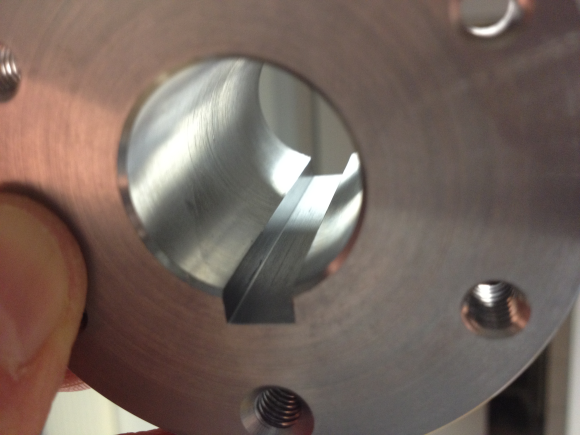

- Automatically correctly positioned and repeatable clamping of the tools

- Stroke setting by direct entry or "teach in" function

- Direct input for the keyway depth setting without test cutting to determine the depth

- Stroke limitation for smaller tool sets

- Automatic radian measurement calculation

- Central power flow due to central design

- Steuerung Siemens S7-1200

- Touchpanel Siemens KTP 700 (easy) ie KTP 400 (eco)

| Machine type | HNZ 32/400 eco | HNZ 50/350 easy | HNZ 50/500 easy | HNZ 70/650 easy | HNZ 100/800 easy |

|---|---|---|---|---|---|

| Keyway width max. (mm) | 32 | 50 | 50 | 70 | 100 |

| Stroke max. (mm) | 400 | 350 | 500 | 650 | 800 |

| Cutting force max. (kn) | 10 | 20 | 20 | 30 | 40 |

| Cutting speed (m/min) | 1 - 20 | 1 - 20 | 1 - 20 | 1 - 20 | 1 - 20 |

| Return speed (m/min) | max. 30 | max. 30 | max. 30 | max. 30 | max. 30 |

| Drive rating (kW) | 3 | 5,5 | 5,5 | 5,5 | 7,5 |

| Machine height (mm) | 1050 | 1100 | 1250 | 1550 | 1900 |

| Floor space BxT (mm) | 700 x 900 | 900 x 900 | 900 x 900 | 1000 x 1000 | 1100 x 1200 |

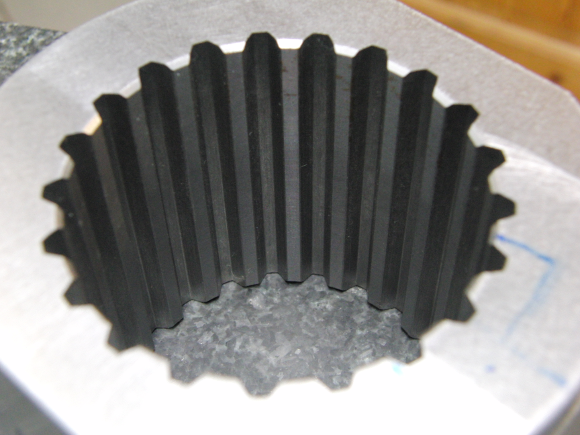

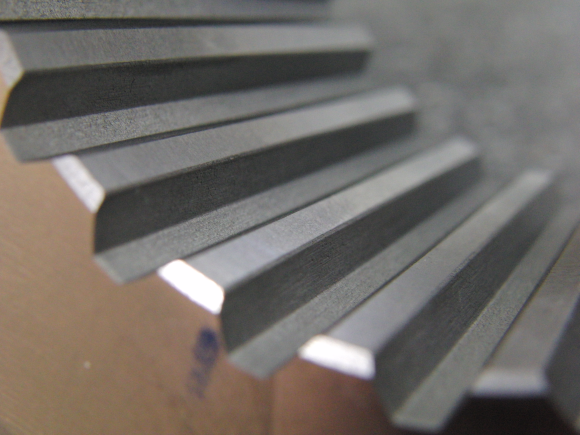

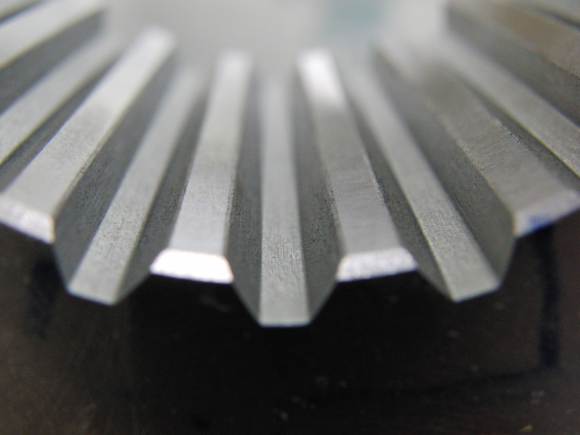

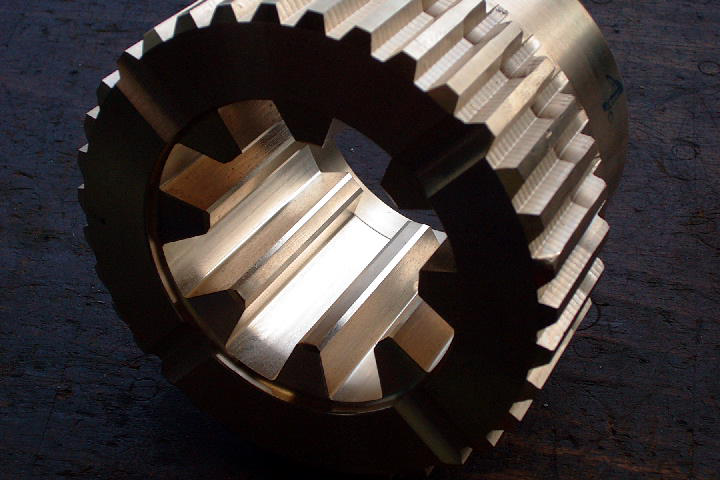

Simple, manual or automatic dividing tables integrated into the machine controls are available for manufacturing multiple slots, spline and teeth profiles.

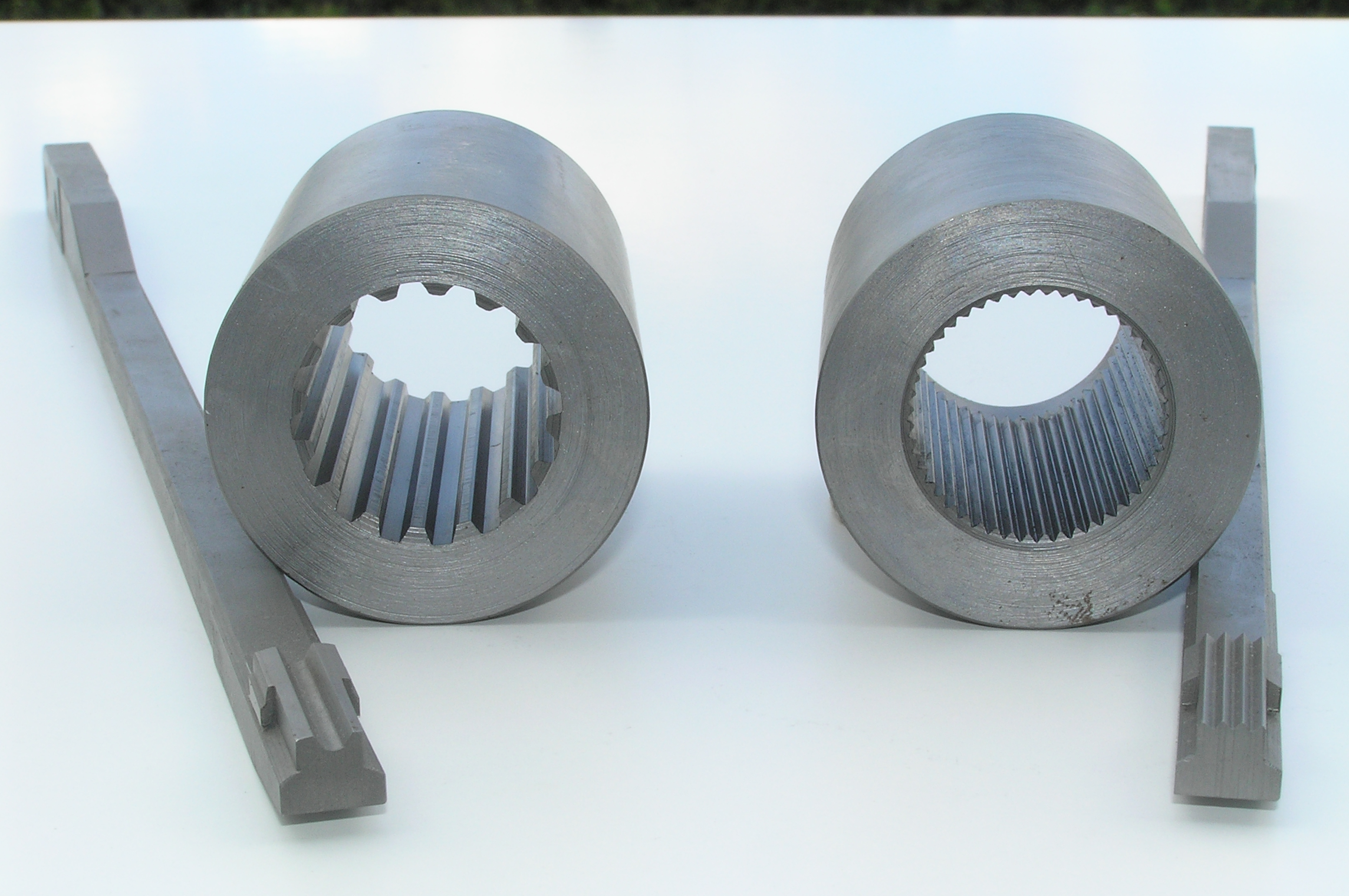

Deliverable tools include cutterbars (also called cutter holder), feedbars, columns (also called guide bars), centring cones, stepped centring bushes, adjustable centring and clamping pieces.